About us

Focus on the existing and sustainable development problems of the industry, and provide solutions through technological innovation.

News

Learn about the latest company, products, business news and technological developments of SHEMAR POWER. Every day, SHEMAR is bringing safer and more economical electric energy closer to you.

Problems found

Electricity is the most important terminal energy source for mankind. The reliability and economy of electricity directly affect the competitiveness of every country and enterprise. In the past 100 years, the immaturity of traditional power external insulation technology has caused the largest number of grid accidents and the largest waste. It is specifically manifested in: the external insulation of power transmission has problems such as wind deviation, pollution flashover, rain flashover, ice flashover, and guano flashover; the external insulation of substation has problems such as explosion, pollution flashover, brittle failure, etc.; The external insulation of the power distribution has problems such as lightning tripping, lightning disconnection, and guano flashover. According to incomplete statistics, traditional external insulation products account for about 3% of the primary construction cost of the power grid, but 60-70% of the annual maintenance and repair costs of the power grid are used for external insulation. The global annual loss caused by external insulation failure exceeds 400 billion yuan, and this data is still growing every year.

-

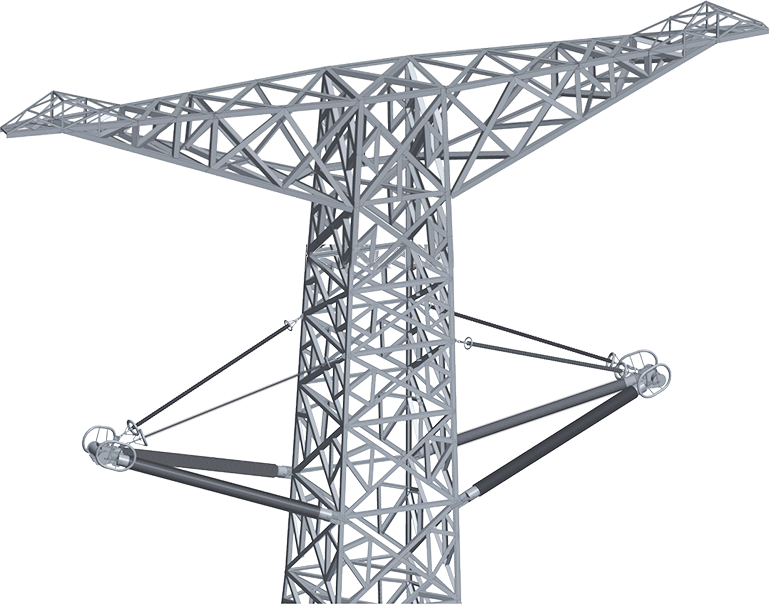

Transmission

wind deviation

wind deviation pollution flashover

pollution flashover rain flashover

rain flashover ice flashover

ice flashover and guano flashover

and guano flashover -

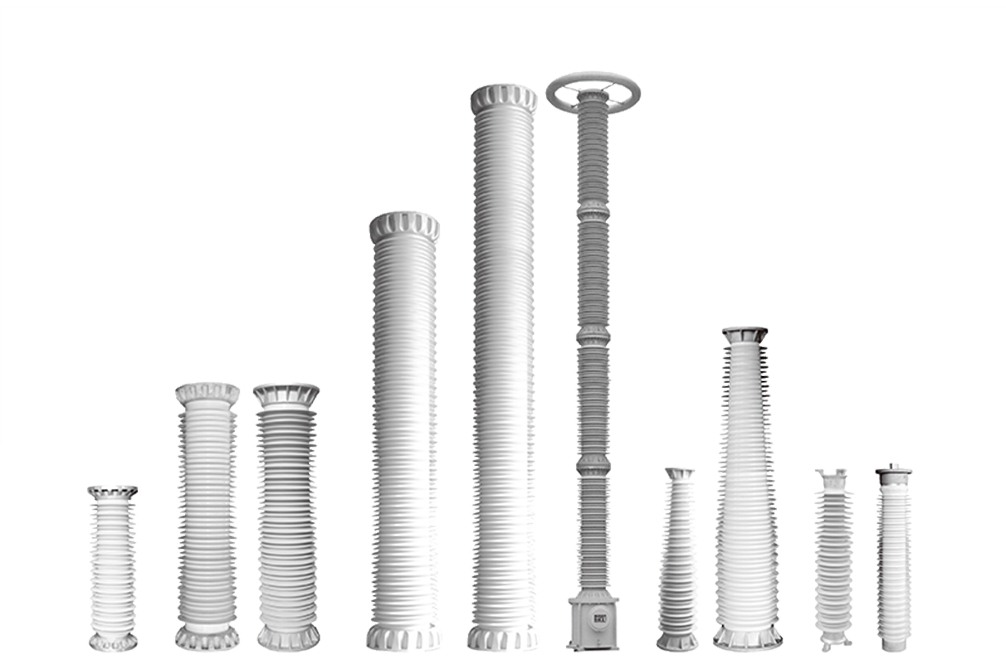

Substation

explosion

explosion pollution flashover

pollution flashover rain flashover

rain flashover ice flashover

ice flashover brittle failure

brittle failure -

Distribution

lightning tripping

lightning tripping lightning disconnection

lightning disconnection and guano flashover

and guano flashover pollution flashover

pollution flashover

Solve the problem

The reliability and economy of the power grid depend on the reliability and economy of the materials used in power equipment.123

Following the law, since SHEMAR’s establishment in 1996, SHEMAR has always focused on the existing and sustainable development issues of the power industry, applying new materials, developing new products, carrying out technological innovation, solving industry problems, and promoting global industry progress. After years of tackling key problems, SHEMAR has successively developed new long-life power transmission, substation and distribution composite external insulation products with technologies that fill the gap in the world, all of which can achieve 40 years of maintenance-free operation, which not only fundamentally solves the reliability of traditional power external insulation problems but also can significantly reduce the operation and maintenance costs of the grid.

30 years of free operation and maintenance

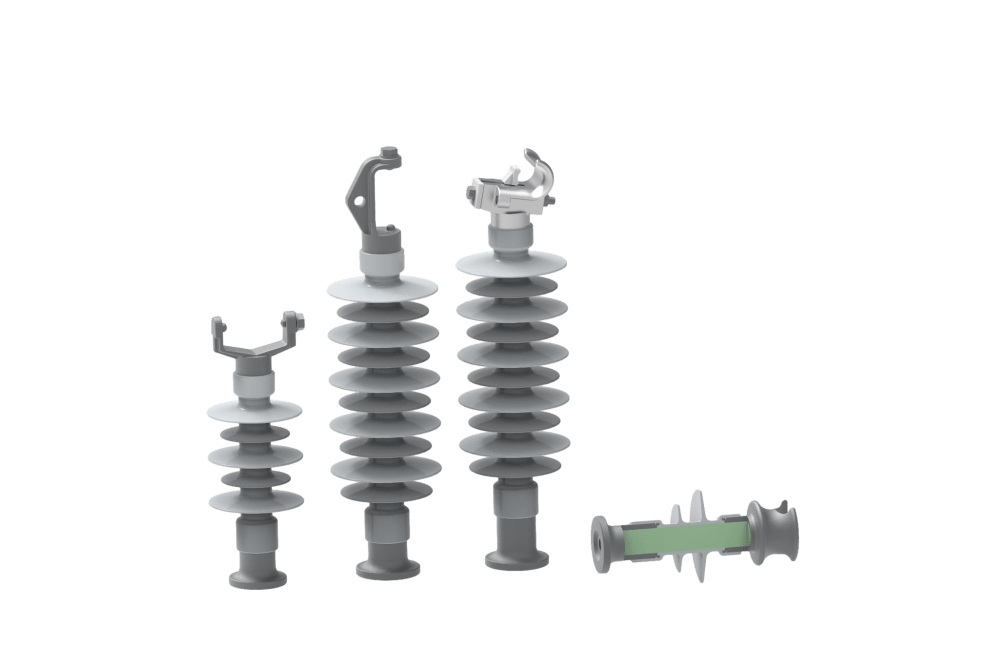

Silicone rubber composite insulators have been widely used in power systems due to their light weight, high mechanical strength, excellent water repellency, unique water repellency, and good anti-fouling, moisture, and rain flashover performance.

Throughout the actual operating conditions, some manufacturers' composite insulator auxiliary shed materials have experienced aging phenomena such as hardening, brittleness, chalking, cracking, cracking, corrosion, decrease in hydrophobicity, local heating, and obvious decrease in mechanical strength, which seriously affect the composite insulator’s safe operation and service life of insulators.