About us

Focus on the existing and sustainable development problems of the industry, and provide solutions through technological innovation.

News

Learn about the latest company, products, business news and technological developments of SHEMAR POWER. Every day, SHEMAR is bringing safer and more economical electric energy closer to you.

Transmission

Substation

Distribution

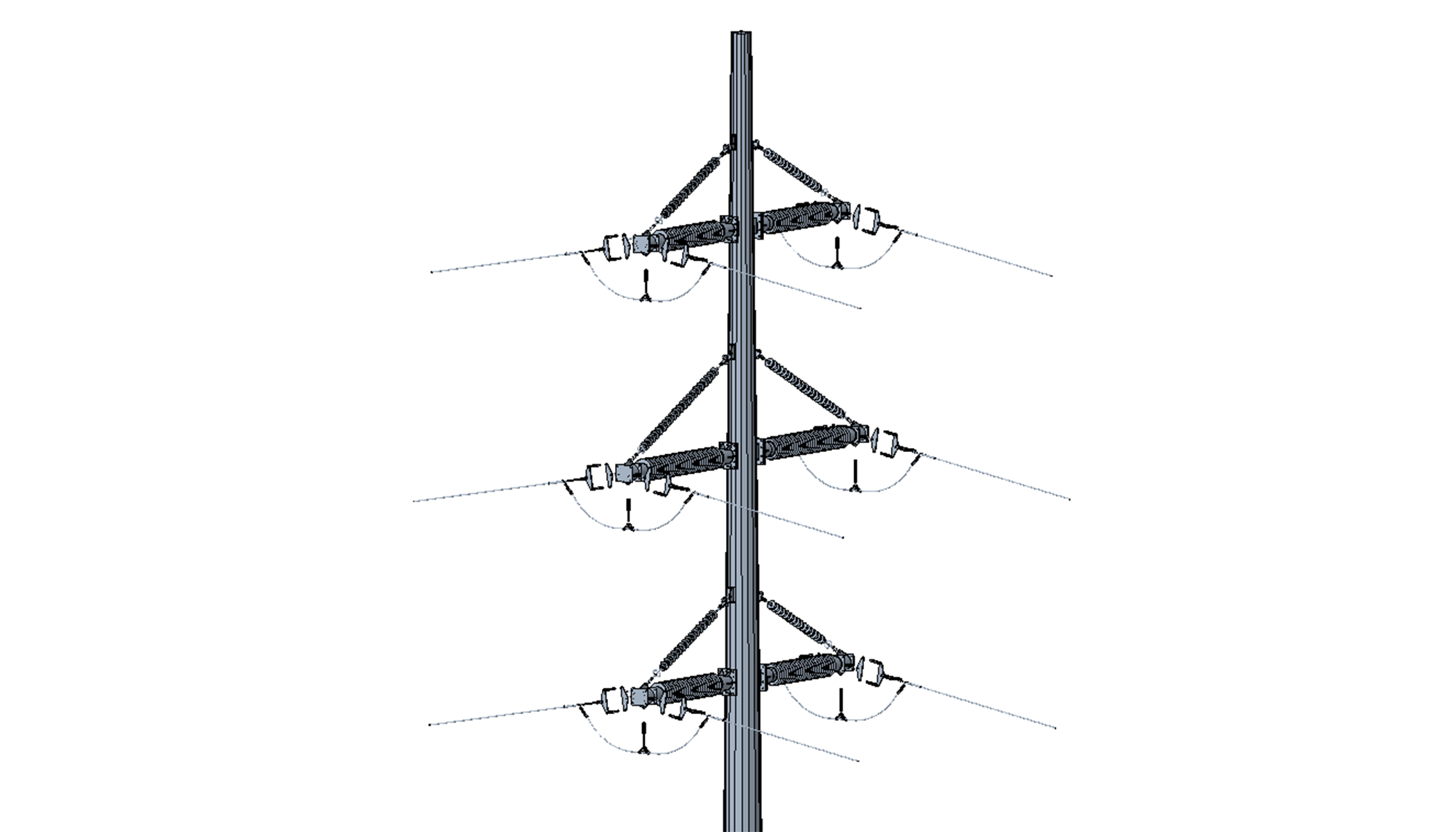

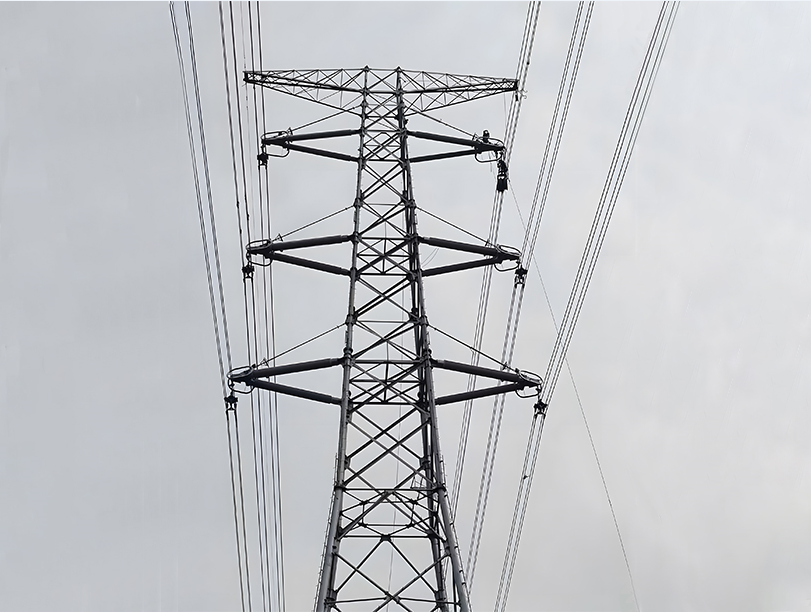

Composite Insulated Cross-Arm

CICA is assembled from insulators and replaces the original iron crossarms and suspension insulator strings with a horizontal layout. The end sections are directly connected to the conductors using suspension fittings, achieving a compact tower design structure. This effectively reduces accidents and losses caused by flashovers while providing mechanical support and electrical insulation for overhead conductor systems.

-

The 400kV Overhead Transmission Line for the Hinkley Point C Nuclear Power Project in the UK

The highest AC voltage used in Europe is 400kV. The "diamond-shaped" composite cross-arm towers were applied in the Hinkley Point C Nuclear Power Transmission Project in the UK in 2015. The project involved various tower forms, including straight sections, corners, and tension towers.

-

The 220kV Overhead Transmission Line Project in the Democratic Republic of Congo in 2022.

Reduce tower height by at least 6 meters. Reduce right-of-way, lowering Bill of Quantities (BOQ) and Right-of-Way (ROW) costs.

-

The 220 kV Jodhpur Bikaner Transmission Line Project by Avaada, India in 2021.

Raising the conductor-to-ground distance to 2 meters effectively reduces the cost of the transmission line project.

-

The 220kV Zhaoqun-Jiatong Energy Transmission Line Project in Nantong, Jiangsu, China.

Minimizing capital expenditure of the project: reducing raw materials and lowering construction workload. Reducing the use of steel and foundation materials to minimize carbon emissions. Excellent resource coordination to shorten the project delivery period. Decreasing operational expenses of the project: Using CICA technology can reduce operating and maintenance costs, as well as losses resulting from power outages after project completion.

-

The 500kV Datang Leizhou Power Plant Phase I Interconnection System Project in Zhanjiang, Guangdong, China in 2018.

The project is located in Leizhou City, Zhanjiang, Guangdong Province, China. This area is a typical coastal region with high salinity, located near the Qiongzhou Strait. The wind intensity is significantly higher than inland areas, and the region is also prone to severe weather conditions such as typhoons and heavy rainfall.

-

The XiMeng - Shengli 1000kV UHV Transmission Line Project, China in 2015.

The world's first application of composite crossarm towers in an ultra-high voltage alternating current (UHVAC) transmission line project.

-

The ±800kV Lingzhou-Shaoxing UHVDC Transmission Line Project, China in 2015.

The world's first application of composite crossarm towers in an ultra-high voltage direct current (UHVDC) transmission line project.

-

The 750kV Second Channel Project connecting Xinjiang with the Northwest Main Grid, China in 2013.

The world's first application of composite crossarm towers in an ultra-high voltage transmission line project. Utilization of 7 foundation straight-line towers.

-

The TATA Power 220kV Composite Crossarm Project, India in 2022.

Using the CICA solution to optimize tower height while maintaining the existing corridor width, achieving the required airspace for aviation.

-

The Transelec 500kV CICA Project, Chile in 2022.

The conductor suspension point was raised by approximately 2 meters, effectively resolving the issue of insufficient ground clearance distance in the original line.

-

The 240kV Project, Canada in 2020.

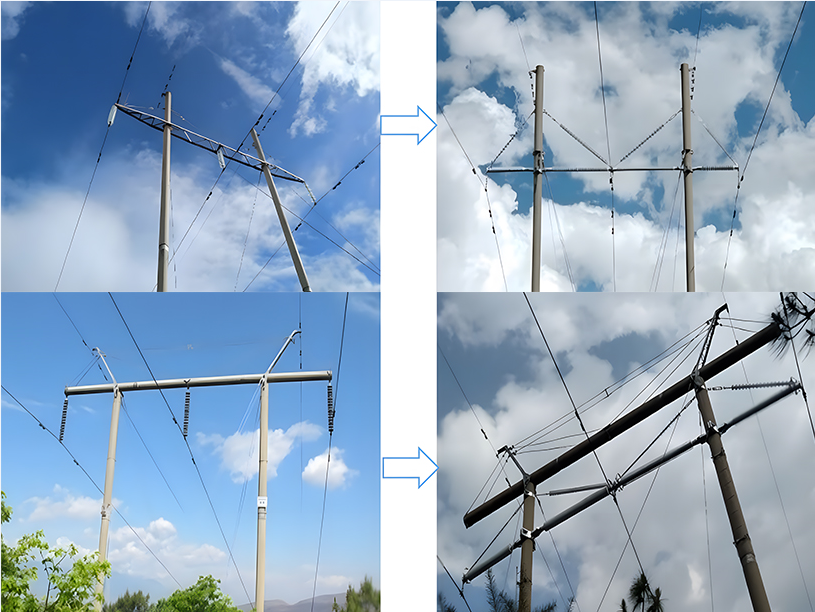

The Canadian company aims to increase the ground clearance for the 240kV double-circuit lattice tower conductors in order to address land occupancy issues. They plan to replace the angle steel crossarms with dual-pole dual-tension composite crossarms to elevate the conductors and improve the ground clearance distance.

-

The 132kV Transmission Line Project in Hyderabad, India in 2019.

The project addressed the issues of restricted corridor space and inadequate ground clearance, thereby enhancing the safety and reliability of the power grid operation.

-

The 110kV Tianqing Line and 220kV Manxia Line Technical Transformation Project in Dali, Yunnan, China in 2018.

The project involved studying the use of composite material crossarms to reduce the corridor width of the line in Dali, Yunnan, China, taking into consideration the area's unique geographical environment with high altitude, strong UV radiation, and mountainous terrain. This approach improved construction efficiency while effectively reducing the risk of flashovers caused by lightning strikes, wind-induced deflection, bird damage, and other factors. Furthermore, it lowered operating and maintenance costs.

-

The 500kV Technical Transformation Project of the Dongsan Line in Jiangsu, China in 2016.

Since its commissioning in 2000, the line has experienced multiple instances of wind-induced deflection. Various methods to prevent wind-induced deflection have been employed, but they have not completely improved the effectiveness in preventing deflection-related tripping accidents.

-

The 220kV Maoqiang Line Transformation Project in Lianyungang, Jiangsu, China in 2022.

Located in a coastal area, the line has been severely corroded and has withstood multiple strong typhoons, yet continues to operate normally.